Compressed air enhancement systems have and added advantage over fan or other types of blower. The compressed air used is typically much dryer than the ambient air. This being the case the localised air around the product being dried will be maintained at a lower humidity and hence have a higher moisture absorption rate. In humid ambient environments, as found in many production environments, this means that compressed air-drying systems can offer increased drying.

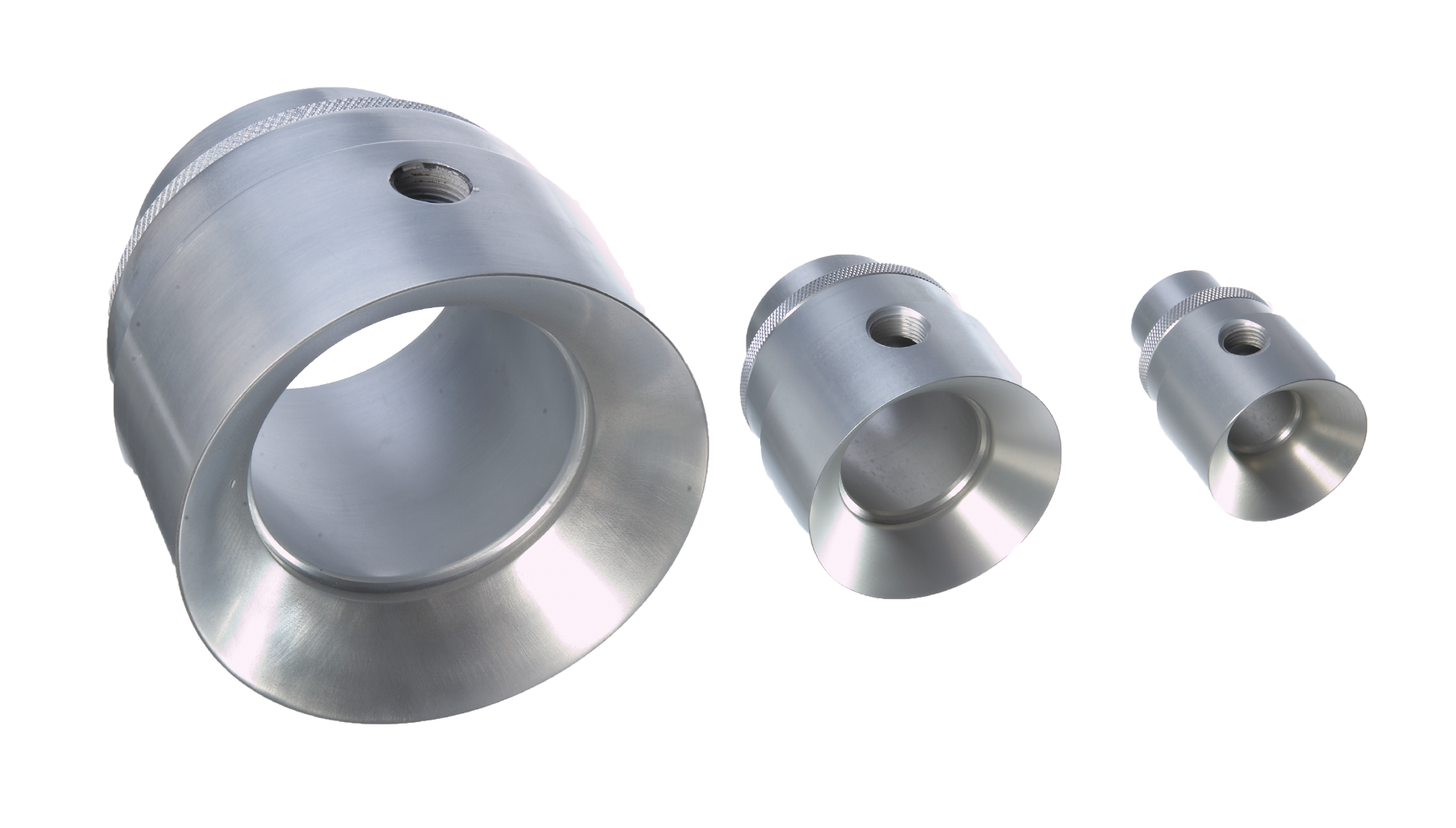

When selecting compressed air enhancement products for drying applications it is, generally, the volume of air moved over the target that is of primary concern. With large volumes of air being moved continually over the drying target we help maintain the necessary low humidity of the localised air and, hence, improve the rate of drying. As such air amplifier are often a very good choice of product for drying processes that rely entirely on evaporative drying. Air amplifiers can entrain surrounding air by up to a factor of 17:1 meaning that for every m3 of compressed air put through the amplifier 17m3 of ambient air will be entrained and moved. These large air volumes tend to move fairly gently when compared to the air streams produced by other compressed air enhancement devices like air knives. Again, this might be an advantage in many drying applications where powerful, high force, air currents might damage the product being dried.